Difference between revisions of "ISO26262/Home"

| (5 intermediate revisions by the same user not shown) | |||

| Line 13: | Line 13: | ||

The purpose of this project is to lower the investment in both time and cost needed to introducte ISO26262 into small and medium sized companies (SME's). In order to reach this goal informed decisions made by our project partners are documented, together with their rationale, to enhance decision making in future projects. | The purpose of this project is to lower the investment in both time and cost needed to introducte ISO26262 into small and medium sized companies (SME's). In order to reach this goal informed decisions made by our project partners are documented, together with their rationale, to enhance decision making in future projects. | ||

Particular challenges in the implementation process of ISO26262 are addressed and the solutions will be explained. | Particular challenges in the implementation process of ISO26262 are addressed and the solutions will be explained. | ||

| − | Also templates are made to aid in the process of new document creation to save both time and money. These templates are provided with hints and examples. In addition to this two real-life use cases are added to each milestone: the VSE use-case and the e-Traction use-case. | + | Also templates are made to aid in the process of new document creation to save both time and money. These templates are provided with hints and examples. In addition to this two real-life use cases are added to each milestone: the VSE use-case and the e-Traction use-case. Also, Brace has added contributed with their own case study, evaluating the functional safety of a pre-ISO26262 cruise control system. |

| − | This wiki is set up according to the same structure as the V-Cycle which is also referred to in the ISO26262. (picture below) | + | [[ISO26262/VSE_Use-Case|Please click here to read more about the VSE use-case.]] |

| + | |||

| + | [[ISO26262/e-Traction_Use-Case|Please click read more about the e-Traction use-case.]] | ||

| + | |||

| + | [[ISO26262/Brace_Use-Case|Please click here to read more about the Brace use-case.]] | ||

| + | |||

| + | This wiki is set up according to the same structure as the V-Cycle which is also referred to in the ISO26262. (see picture below) | ||

| + | |||

| + | |||

| + | ''Hint: click on a chapter in the image to be redirected to that page.'' | ||

| Line 39: | Line 48: | ||

rect 630 200 865 230 [[ISO26262/V-Cycle/4-10_Functional_Safety_Assessment| 4-10 Functional Safety Assessment| 4-10 Functional Safety Assessment]] | rect 630 200 865 230 [[ISO26262/V-Cycle/4-10_Functional_Safety_Assessment| 4-10 Functional Safety Assessment| 4-10 Functional Safety Assessment]] | ||

rect 630 160 865 190 [[ISO26262/V-Cycle/4-11_Release_for_Production| 4-11 Release for Production| 4-11 Release for Production]] | rect 630 160 865 190 [[ISO26262/V-Cycle/4-11_Release_for_Production| 4-11 Release for Production| 4-11 Release for Production]] | ||

| − | rect | + | rect 285 330 555 375 [[ISO26262/V-Cycle/5._Product_development_at_the_hardware_level| 5. Product development at the hardware level]] |

| − | rect | + | rect 300 375 540 400 [[ISO26262/V-Cycle/5-5_Initiation_of_Product_Development_at_the_Hardware_Level| 5-5 Initiation of Product Development at the Hardware Level]] |

| − | rect | + | rect 300 400 540 435 [[ISO26262/V-Cycle/5-6_Specification_of_Hardware_Safety_Requirements| 5-6 Specification of Hardware Safety Requirements]] |

| − | rect | + | rect 300 435 540 460 [[ISO26262/V-Cycle/5-7_Hardware_Design| 5-7 Hardware Design]] |

| − | rect | + | rect 300 460 540 505 [[ISO26262/V-Cycle/5-8_Evaluation_of_the_Hardware_Architectural_Metrics| 5-8 Evaluation of the Hardware Architectural Metrics]] |

| − | rect | + | rect 300 505 540 545 [[ISO26262/V-Cycle/5-9_Evaluation_of_the_Safety_Goal_violations_due_to_Random_Hardware_Failure| 5-9 Evaluation of the Safety Goal violations due to Random Hardware Failure]] |

| − | rect | + | rect 300 545 540 585 [[ISO26262/V-Cycle/5-10_Hardware_Integration_and_Testing| 5-10 Hardware Integration and Testing]] |

| − | rect | + | rect 615 330 885 365 [[ISO26262/V-Cycle/6._Product_development_at_the_software_level| 6. Product development at the software level]] |

| − | rect 0 | + | rect 0 640 1140 670 [[ISO26262/Supporting_Processes| 8. Supporting Processes]] |

desc none | desc none | ||

</imagemap> | </imagemap> | ||

| Line 53: | Line 62: | ||

| − | + | [[ISO26262/Useful_Links| Go to page: Useful Links]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[ISO26262/Useful_Links]] | ||

Latest revision as of 10:08, 18 October 2017

Back to Home

Welcome to the ISO26262: Recommended Practice. This is the result of a project which is set up by HAN-Automotive Research, in cooperation with Baesis, BRACE, VSE and e-Traction.

At this moment the Concept phase and the Development phase at system level are covered.

This project is made possible by our parters who actively contributed: - Baesis, Functional Safety Expert - BRACE, Functional Safety Expert - VSE, implementing ISO26262 - e-Traction, implementing ISO26262

The purpose of this project is to lower the investment in both time and cost needed to introducte ISO26262 into small and medium sized companies (SME's). In order to reach this goal informed decisions made by our project partners are documented, together with their rationale, to enhance decision making in future projects. Particular challenges in the implementation process of ISO26262 are addressed and the solutions will be explained. Also templates are made to aid in the process of new document creation to save both time and money. These templates are provided with hints and examples. In addition to this two real-life use cases are added to each milestone: the VSE use-case and the e-Traction use-case. Also, Brace has added contributed with their own case study, evaluating the functional safety of a pre-ISO26262 cruise control system.

Please click here to read more about the VSE use-case.

Please click read more about the e-Traction use-case.

Please click here to read more about the Brace use-case.

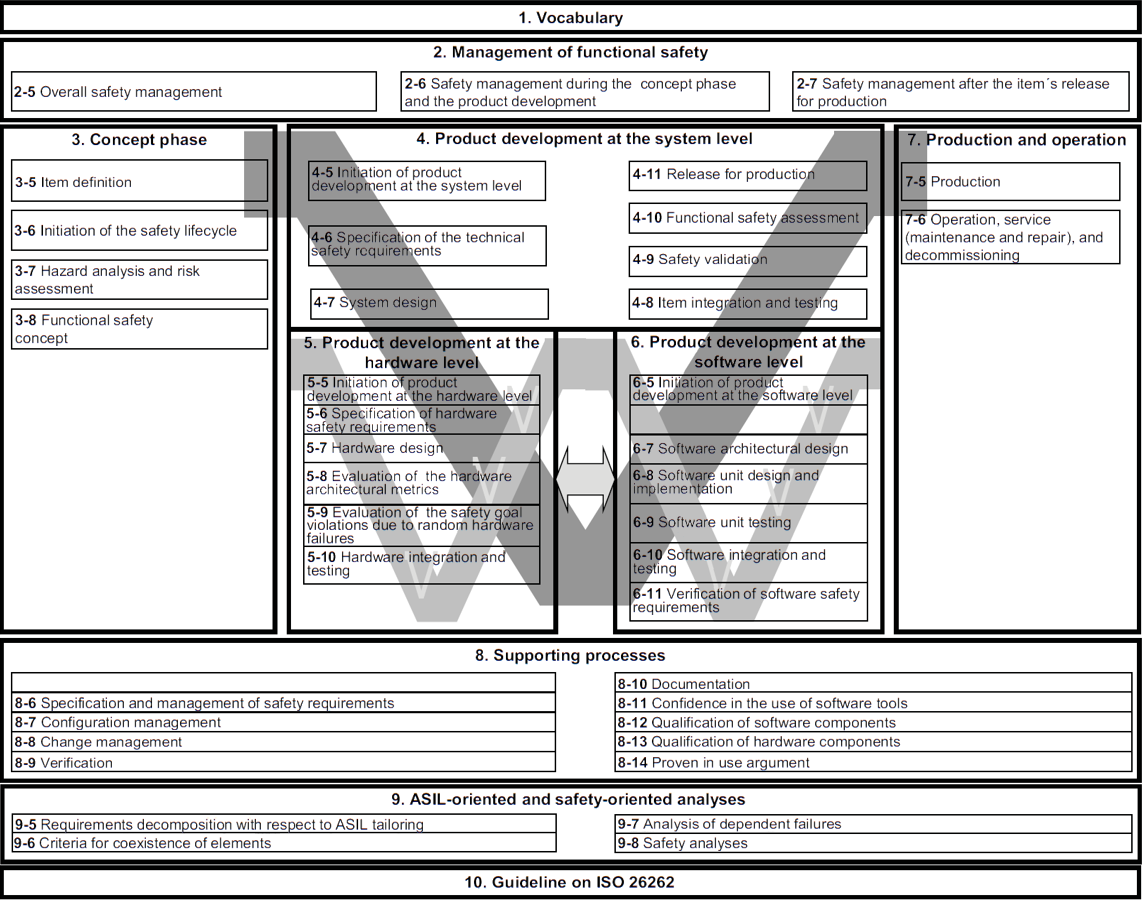

This wiki is set up according to the same structure as the V-Cycle which is also referred to in the ISO26262. (see picture below)

Hint: click on a chapter in the image to be redirected to that page.